Table of Contents

ToggleLego Abandons Crafting Toy Bricks from Recycled Plastic Bottles

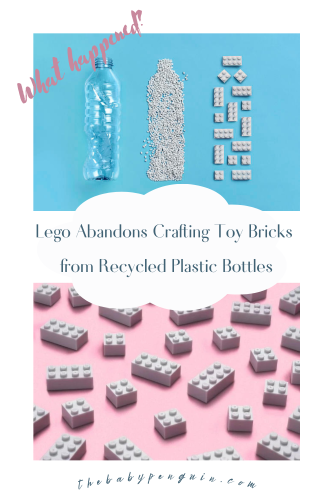

In today’s world, where global sustainability concerns loom large, Danish toymaker Lego has embarked on an extraordinary mission to align its iconic plastic bricks with a more environmentally responsible future. This comprehensive article explores Lego’s ambitious sustainability goals, the hurdles they’ve encountered, and the innovative solutions they’re pioneering. Why did Lego Abandon Crafting Toy Bricks from Recycled Plastic Bottles? Let’s see why they deemed this transition not possible.

Lego’s Sustainability Goals and Challenges

Recognizing the environmental impact associated with their plastic bricks, Lego initiated their sustainability journey in 2020. Their mission? To replace conventional plastic bricks with eco-friendly alternatives while preserving the color, shine, and sound that defines Lego play. This undertaking, however, posed a formidable challenge.

“In the early days, the belief was that it was easier to find this magic material or this new material” that would solve the sustainability issue, Christiansen said, but “that doesn’t seem to be there. We tested hundreds and hundreds of materials. It’s just not been possible to find a material like that.”

Exploring Alternative Sustainable Materials

To address this challenge head-on, Lego’s dedicated scientists and engineers have been tirelessly testing and developing bricks made from a diverse range of alternative sustainable materials. One such material in the spotlight is e-methanol, a green methanol produced through renewable energy and waste carbon dioxide. Understanding the intricacies of e-methanol production and its potential to revolutionize plastic manufacturing sheds light on Lego’s innovative approach.

Moreover, Lego has seamlessly integrated bio-polypropylene—a sustainable variant of polyethylene—into specific parts of Lego sets, including leaves, trees, and other accessories. This choice not only enhances sustainability but also preserves the quality and integrity of the Lego building experience.

Measuring the Impact

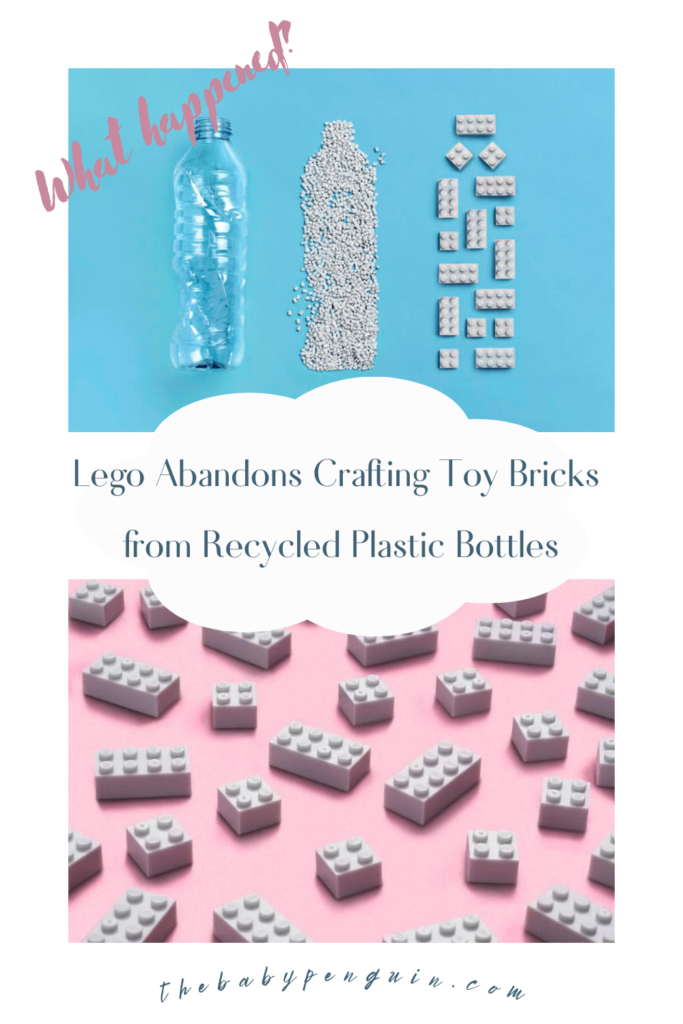

Lego’s commitment to sustainability goes beyond mere rhetoric; it’s about tangible change. The company has invested a staggering $1.2 billion in sustainability initiatives, with an ambitious target of reducing carbon emissions by 37% by 2032. This commitment extends far beyond their bricks, encompassing broader environmental objectives. Efforts to reduce carbon emissions have been a central focus of Lego’s mission. Their scientists and engineers conducted exhaustive tests on over 250 variations of PET materials and numerous other plastic formulations before finalizing prototypes. On average, a one-liter plastic PET bottle yielded enough raw material for ten 2 x 4 Lego bricks. This rigorous research exemplifies Lego’s unwavering dedication to sustainable solutions.

Furthermore, Lego’s sustainability initiatives have extended to various facets of their business, resulting in positive environmental impacts. Initiatives such as waste reduction and exploration of advanced recycling technologies have contributed significantly to a more eco-friendly future. As Lego continues to navigate the intricate landscape of sustainability, their unyielding commitment to innovation and positive environmental change serves as a compelling example of a beloved brand taking meaningful steps toward a greener, more sustainable world.

No Easy Road to Success

On September 24th, Danish toymaker Lego made a pivotal announcement. Initially, their high-profile endeavor aimed to replace oil-based plastics in their iconic bricks with sustainable alternatives. However, a significant challenge emerged when their new material was found to contribute to higher carbon emissions, a revelation reported by the Financial Times. Lego’s journey led them to test bricks made from recycled polyethylene terephthalate (RPET), only to discover that this approach would result in increased carbon emissions. Lego’s CEO, Niels Christiansen, acknowledged these difficulties, stating, “We tested hundreds and hundreds of materials. It’s just not been possible to find a material like that.”

Despite this setback, a Lego spokesperson assured Reuters that the company remained steadfast in its commitment to sustainability goals. They persisted in testing and development, with the goal of producing toys from sustainable materials by 2032. Lego’s pursuit of sustainability began in 2020 when they initiated efforts to replace plastic bricks with eco-friendly options. The primary challenge lay in finding a material that met environmental criteria while still delivering the same color, shine, and sound characteristics of oil-based plastic bricks.

The PET prototype had been celebrated in 2021 as the first recycled alternative to meet Lego’s stringent quality, safety, and play standards. However, further experimentation proved its durability was insufficient. Throughout their quest for sustainable materials, Lego’s scientists and engineers assessed over 250 variations of PET materials and numerous other plastic formulations. Ultimately, they created a prototype using plastic from approved suppliers in the U.S., with each one-liter PET bottle yielding enough raw material for ten 2 x 4 Lego bricks.

Can Plastic Toys be Eco-Friendly? What Types of Plastics are Safe?

What was the Problem?

Tim Brooks, Lego’s Head of Sustainability, explained that working solely with RPET (recycled polyethylene terephthalate) presented certain challenges. RPET, on its own, was softer than ABS (acrylonitrile butadiene styrene), necessitating the addition of extra ingredients to match the safety and durability of existing plastic. Additionally, processing and drying RPET demanded significant energy inputs. To illustrate this, he likened it to attempting to build a bike out of wood instead of steel, emphasizing the difficulty of achieving comparable results.

Furthermore, in order to scale up production of recycled PET, a complete overhaul of their manufacturing processes would have been required, resulting in substantial disruptions to their operations. Surprisingly, despite these efforts, it was anticipated that the carbon footprint of production would actually increase. This outcome left the Lego team disappointed.

Shift of Focus

Consequently, Lego has shifted its focus to making individual components of ABS (acrylonitrile butadiene styrene) more sustainable. This involves a gradual transition towards incorporating more bio-based and recycled materials into these components. Niels Christiansen, Lego’s Chief Executive, clarified that this shift wouldn’t instantly turn everything 100% sustainable, but rather elements of the products would be based on bio or recycled materials, possibly comprising 50%, 30%, or 70% of the material composition. Initially, it would be challenging to provide precise figures on emission reductions for individual sets due to this approach, posing communication challenges with consumers.

Nevertheless, Lego’s CEO firmly believes that this new direction aligns with their long-term objectives. The company aims to achieve a 37% reduction in emissions by 2032 compared to 2019 and to exclusively use sustainable materials by that time. To support these goals, Lego plans to triple its annual spending on sustainability to DKr3bn ($430 million) by 2025. Christiansen acknowledged that this increased investment might affect profit margins, as the company does not intend to pass on the higher cost of sustainable materials to consumers.

Conclusion:

As Lego diligently forges ahead with their sustainability journey, they continue to explore innovative solutions that align with their environmental objectives. Founded in 1932, Lego, meaning “play well” in Danish, has been synonymous with creative play, and their current commitment to sustainability seeks to apply this ethos toward building a brighter, more sustainable future for their iconic bricks. We see many new technologies and innovation present unforeseen challenges. It seems Lego will be steadfast with its effors to secure a more sustainable tomorrow for our children. If you would like to learn more about some of the best sustainable toy companies, please see my article below.

3 Reasons to Subscribe to The Baby Penguin

- Discover new eco-friendly toys! By subscribing to The Baby Penguin, you can stay up-to-date on the latest eco-friendly toys and products that are good for your child and the planet. You’ll learn about the newest sustainable products.

- Learn about sustainable practices! Our store and blog will also provide valuable information on making more environmentally conscious choices when purchasing toys for your child. You can learn about sustainable manufacturing practices, materials, packaging, and tips for reducing waste in your home.

- Support a mission-driven business! Subscribing to our sustainable toy store and blog means supporting a company committed to positively impacting the environment and society. By choosing to shop from an eco-friendly, you’re helping to promote sustainability in the toy industry and beyond.